- Call: +86-13584426116

- Email: info@borun-machinery.com

- Get a Quote

PVC pipes are widely used in different areas including the industry and in housing. They are used successfully for the construction of pipes necessary for the transport of virtually any liquid or gas. Plastic pipes are chosen for the construction of sewer systems, including external networks, pipes, gutters and drainage systems. This widespread use is due to the excellent features such as their resistance to corrosive fluids, their adaptability to a fairly wide temperature range, the ease of installation and assembly of the pipes and their long shelf life and durability.

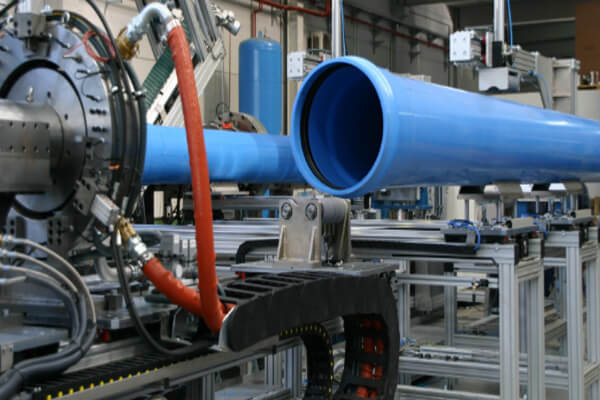

In the PVC pipe extrusion production line factory, the extrusion method is employed in the production process. There are polymeric raw materials and special equipment are used in addition to conditions such as temperature and pressure which are controlled during the PVC production process.

In this post, we will be considering how the production of PVC pipes is carried out and the materials, equipment and conditions which are required in the production process. Let's get started!

To carry out the production of PVC pipes, granulated PVC polymer is used. And to give pipes special properties, the composition includes additives, which include:

Catalysts are substances capable of accelerating the polymerization reaction;

Inhibitors - Substances that, on the contrary, affect the slowdown of the reaction.

Stabilizers are special substances that give stability to the polymer.

Plasticizers - elements, with the introduction of which the polymer becomes plastic.

Antistatic additives: these substances are introduced to prevent the formation of a static electricity charge.

Pigments or dyes: additives that give the finished product a specific color.

Other special additives can be added to the polymer that regulates the properties of the polymer obtained.

To organize the work, the following equipment is needed for the production of PVC pipes:

Bunker: in which the prepared raw material is poured.

Extruder or PVC pipe extrusion line: the apparatus in which the extrusion process is carried out.

Bathrooms - facilities for cooling and product calibration.

Mechanism for cutting tubes (disc cutters or guillotine shears).

Now, let's take a brief look at the production process.

The tube production process is quite simple, it does not differ in labor intensity and energy consumption. It is safe and environment friendly. The necessary equipment for the production of PVC pipes can be located in an area of about one hundred square meters.

The pipeline extrusion line operates in a technologically complete continuous cycle, which includes:

Extrusion;

Product calibration;

Cooling in special bathrooms;

Exhaust pipe;

Trim at a given length;

The plastic in granules is poured into a bunker in which a screw-shaped screw and thermal heating elements are installed. In the bunker, during rotation, the plastic is heated to the desired temperature (the process is automated). In the molten state, the polymer enters the extrusion die. To form a pipe, special shapes are used, with a specific outer and inner diameter. As a result of the extrusion process, a plasticized tube blank is obtained.

Next, the tube enters the calibration in the vacuum gauge, which is otherwise called a bath. This equipment is a closed container with a length of three meters, in which a vacuum is created using a vacuum pump.

The billet passes through the diaphragm of the caliper and enters the following chamber: the cooling bath, where there is also rarefied air. A traction device is used to uniformly stretch the pipe. It can be tape or tracking type. Pipe cutting is done with a guillotine or a disk saw.

At the end of the technology chain, the finished tubes go to the stacker, an apparatus that places the products on a special shelf.

The production of PVC pipes is not a very laborious and automated process. When organizing the production, the cost of buying the equipment and the initial measures should be considered. However, the PVC pipe extrusion production line price varies according to the model, quality as well as the size of the system. However, it is important to liaise with reputable pvc pipe extrusion line manufacturers to ensure that you get the best for your production needs.