- Call: +86-13584426116

- Email: info@borun-machinery.com

- Get a Quote

PLC Control, high degree of automation;

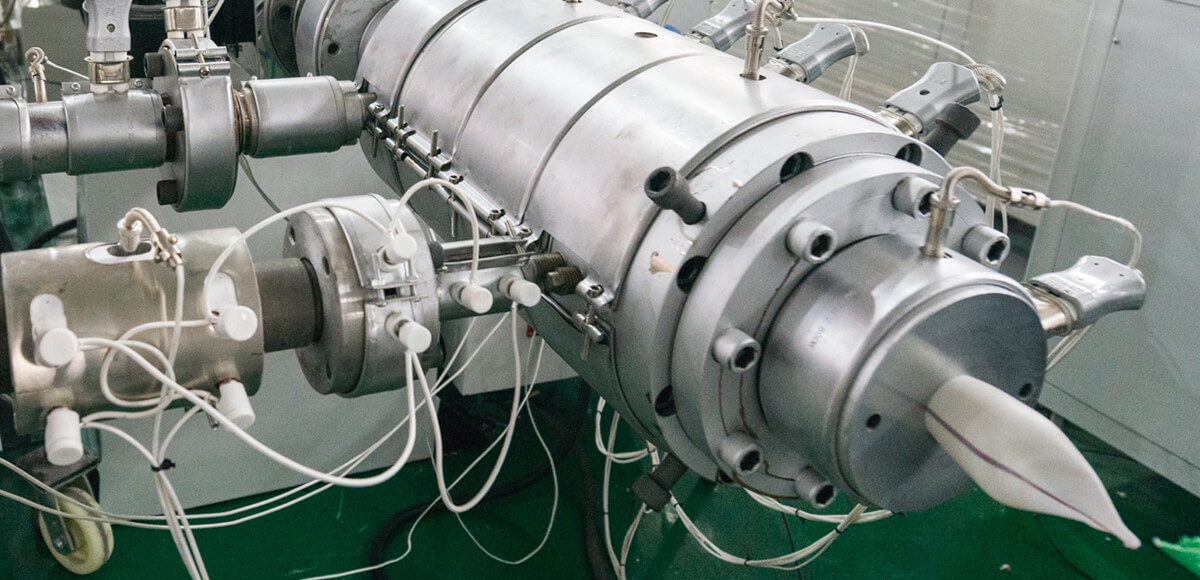

Adopting compound spiral engine head, effectively deleting memory function of the material;

Adopting specialized screw with good plasticizing effect;

Vacuum calibration, constant temperature control, eliminating pipe stress;

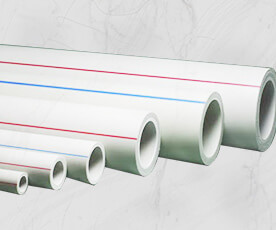

Adopting co-extrusion head to add color line;

High extrusion capacity, low temperature of melt, equal temperature of melt;

Wide processing range of raw materials.

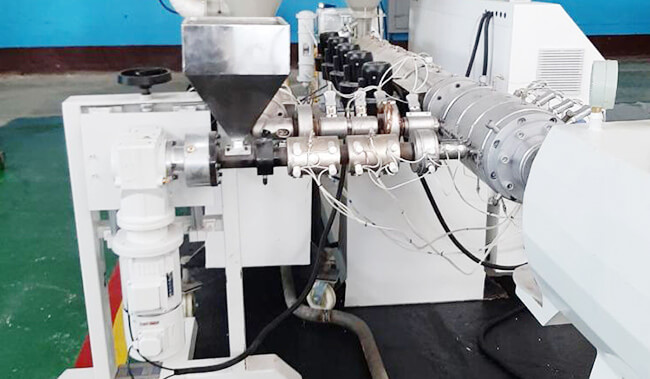

Co-extruder (colour line extruder)

Pipe Extrusion Mould

Calibration Tank

Spraying Cooling Tank

Code Printing

Haul Off Machine

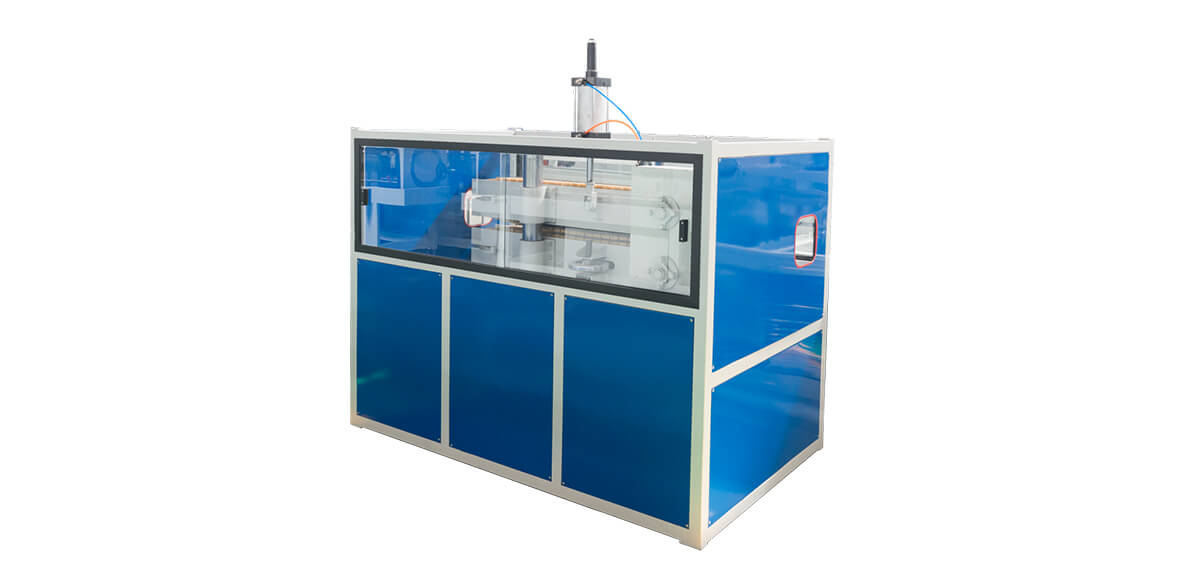

Cutting Machine

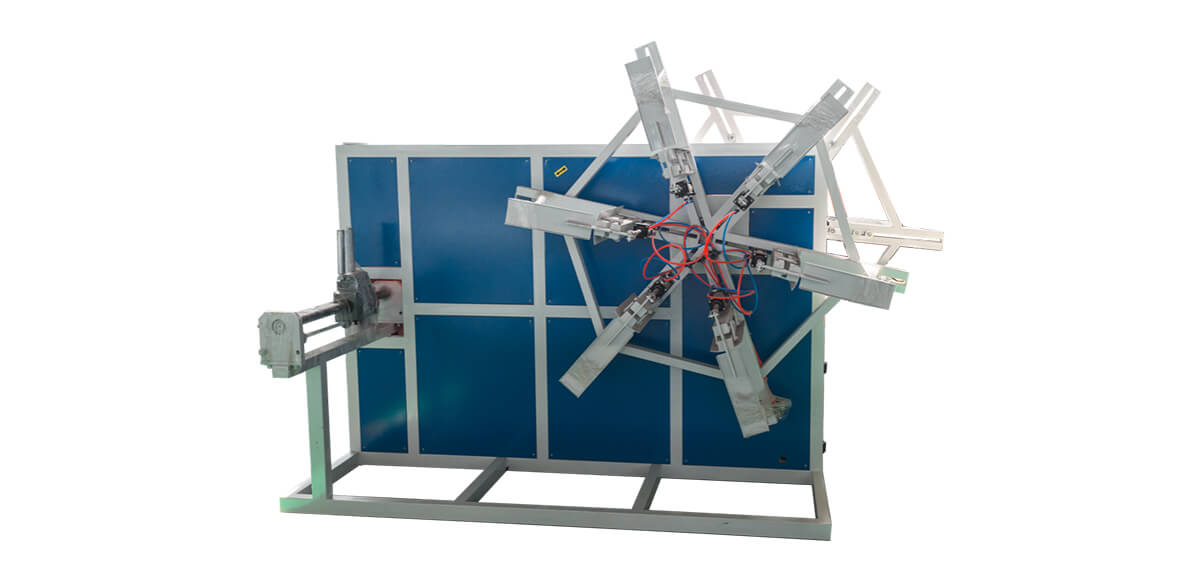

Stacker

Pipe Winder

Single Screw Extruder:

Drive motor: SIEMENS BEIDE;

Inverter: ABB;

Temperature controller: Omron;

Contactor: Siemens;

Material: 40Cr;

Calibrator: Stainless steel or copper material;

We can produce different pipe diameter and thickness by change the core bar and calibrator of the mold, the mold could be customized.

Material: Stainless steel

Tank Movement: front and back by motor driven up and down by manual adjust.

Material: Stainless Steel

Length: 6m or customized

Laser Printing

Haul-off Speed Adjustive: ABB inverter

Above Haul-off Bracket Compaction Mode: Adopt pneumatic gas cylinder

Cutting Saw: Adopt Alloy Steel Saw

Machine Type: No dust cutting machine

This type cutting machine can reduce the dust in your factory, and with lower norise.

Laying Board Material: 1.5mm Stainless Steel Board

Stacking Mode: Stacking by Gas Cylinder, adopt Limited Switch Send out Cutting Signal

Single disk, double disk, three disk winding machines could meet different customers’ need.