- Call: +86-13584426116

- Email: info@borun-machinery.com

- Get a Quote

- In recent years, large caliber pipes, household heat-resistant products (such as car antirust coating, computer shell, wall panel, window profile), fiber-reinforced products (such as pipes, case and other flame-retardant PVC products) and hard films and membrane products used for packaging are under development. In the development process, general resins are mostly used.

- In view of the continuous expansion of PVC application field, the demand for the application of high-performance PVC resin is increasing. With the development of various composite plasticizers, composite flame retardants, heat-resistant modifiers and impact modifiers, PVC products will open a larger market.

- In order to meet the market demand, the manufacturer has launched a series of high-performance new products, such as impact resistant PVC bottle material, special material for heat-resistant electronic appliances, PVC alloy for shoes, medical PVC alloy, flame-retardant and smoke-proof lead-free calcium PVC wire and cable composite material, special material for radiation resistant and antistatic PVC alloy fiber reinforced PVC alloy.

PVC products should be developed and applied vigorously for the sustainable and rapid development of plastic building materials

During the 11th Five Year Plan period, the development of construction industry will open up a broad market development space for the development of plastic building materials industry. The newly-built houses in cities and towns will still develop at a scale of about 500 million square meters every year. In 2010, the level of urbanization is expected to reach more than 45%, and urban infrastructure will be greatly developed.

The national agricultural water consumption accounts for 88% of the total water consumption of the country, reaching 484 billion cubic meters, accounting for 17.3% of the total water resources of the country. 95% of agricultural water consumption belongs to agricultural irrigation water, and its effective utilization rate is only 45% for a long time, which is far lower than that of developed countries.

As a large country lacking water in the world, it is urgent to solve the problem of water, and the development of plastic water-saving equipment is an effective and significant measure. At present, the state actively promotes water-saving irrigation, and the use of plastic water-saving equipment nationwide has become an important part of the promotion of agricultural water irrigation technology, which indeed brings about obvious effects of increasing production, income, water saving, energy saving, etc., and promotes the sustainable development of agriculture.

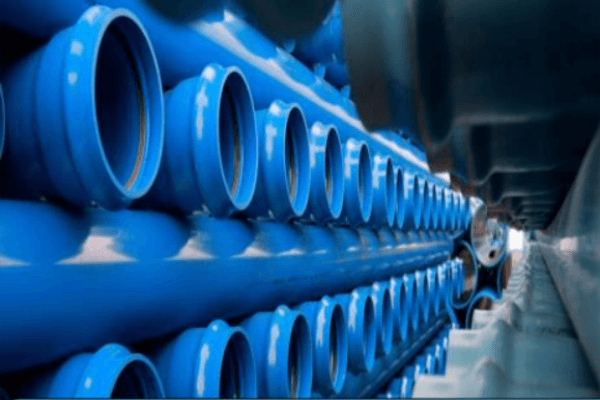

Plastic pipes are the most important new materials for infrastructure construction in urban and rural areas. In 2008, there were more than 1000 plastic pipe production enterprises and more than 3000 production lines in China, with an estimated production capacity of more than 6 million tons and a production capacity of about 4.6 million tons, including 55% PVC pipes, 2.53 million tons; 30% PE pipes, 1.38 million tons; 10% PP pipes, 460000 tons; and 5% other pipes, 230000 tons.

In recent years, the export of plastic pipes has continued to increase. In 2008, China's export of plastic pipes reached 356300 tons, an increase of 22.21% year-on-year, and the export value was US $1.002 billion, an increase of 31.2% year-on-year; the import value was 40800 tons, an increase of - 10.38% year-on-year, and the import value was US $470 million, an increase of 4.94% year-on-year.

In 2009, 80% of plastic pipes will be used in new construction, reconstruction and expansion projects; 70% of building water and drainage pipes will be plastic pipes, and 30% of plastic pipes will be used in urban sewage pipe system; 80% of plastic pipes will be used in building water supply, hot water supply and heating pipe system.

By 2010, new waterproof materials will occupy a leading position in the national waterproof engineering market, reaching more than 70%.

As a new building material, PVC doors and windows are known as the fourth generation of doors and windows after doors and windows, steel doors and windows, and aluminum alloy doors and windows. The application amount of plastic profiles and doors and windows still has a large increase in the whole country. Up to now, there are more than 4000 profile production lines in China, with a total capacity of 5 million tons.

In developed countries, the market share of plastic doors and windows is also the highest, such as 50% in Germany, 56% in France and 45% in the United States, which is about 10 percentage points higher than that of wood windows in the second place.

It is reported that during the 11th Five Year Plan period, plastic doors and windows mainly promoted PVC-U plastics. By 2010, the market share of plastic doors and windows in the country's door and window market can reach more than 40%.

The domestic consumption is dominated by PVC transparent hard products. In recent years, the proportion of hard products in the consumption of PVC has gradually increased, and the proportion of hard products is about 59.2%.

PVC transparent sheet mainly includes semi-rigid sheet, thin sheet, colorless and color transparent plate, which is widely used in the outer packaging of food, drugs, toys, electronic products, handicrafts, tools, clothing and other commodities. At present, there are more than 100 domestic PVC sheet production enterprises with a total production capacity of more than 400000 tons.

With the increasing cultivation area of horticultural facilities and mulching area of plastic film in China, the demand for PVC agricultural film will increase substantially. Due to its high strength and good heat preservation, PVC film is suitable for the areas with cold climate and heavy sandstorm, so it is mainly used in three northeast provinces and some parts of Shandong Province.

In the future, we will focus on solving the problems of anti-aging and anti fog synchronization, anti drop and anti fog. The width of PVC film will be more than 4 meters in the specification of shed film, so it has a good prospect of popularization and application.

Packaging material is the most widely used field in plastic application, and it has always been a large consumer market of PVC. PVC is mainly used as packaging materials for gifts, all kinds of daily necessities and all kinds of furniture. With the rapid development of China's economy and the improvement of people's consumption level, the change of shopping habits will cause a greater pull on the packaging industry.

PVC interior products are one of the largest plastics used in China's automobile industry, ranking the third only after PP and PU.

It is mainly used for roof lining, carpet, inner cover, insulated pipe, fuel filler, door trim strip, corrugated pipe, sealing strip, seat, dashboard skin and other products.

According to the characteristics of automobile industry, strengthening the research of PVC blending modification, reinforcement, filling and flame-retardant, developing alloys and modified raw materials for various accessories, and expanding the application of PVC in automobile industry will be a subject of PVC scientific research industry in the future.

PVC products used in the medical field include various hospital facilities and health care facilities, health care supplies, PVC blood bags, transparent plastic tubes, auxiliary equipment in the operating room, laboratory testing instruments, etc., and there are many potential markets.

Due to its flexibility and low cost, PVC has been widely used in medical products, especially in disposable medical products.