- Call: +86-13584426116

- Email: info@borun-machinery.com

- Get a Quote

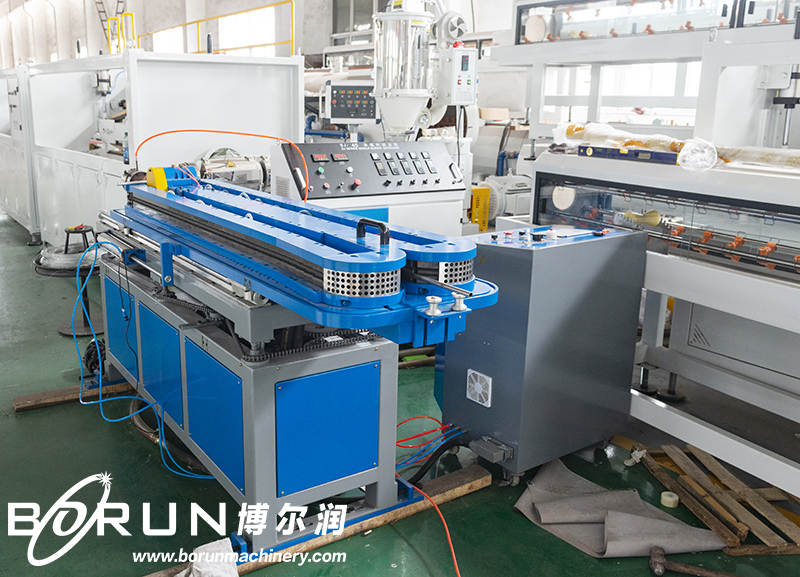

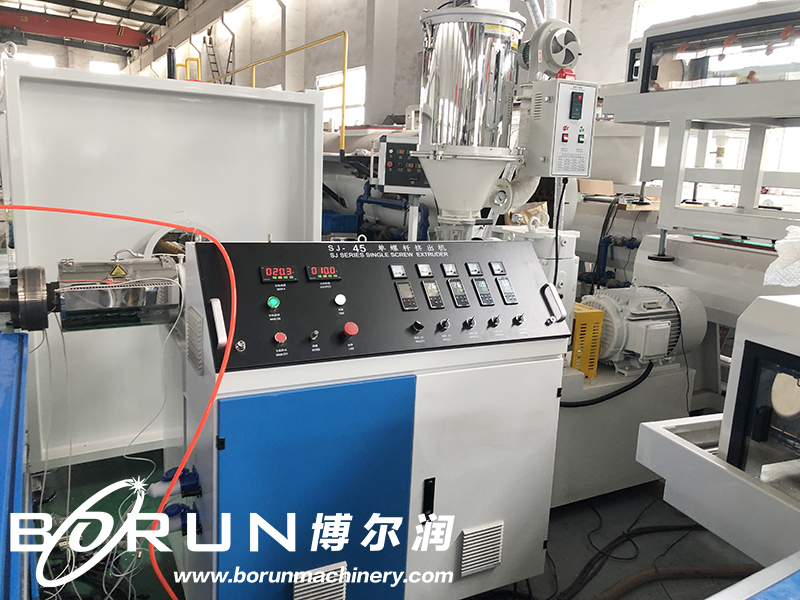

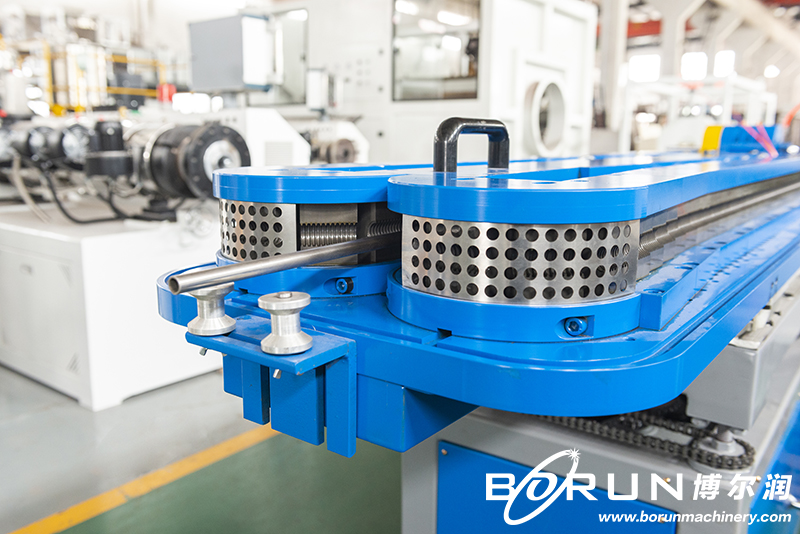

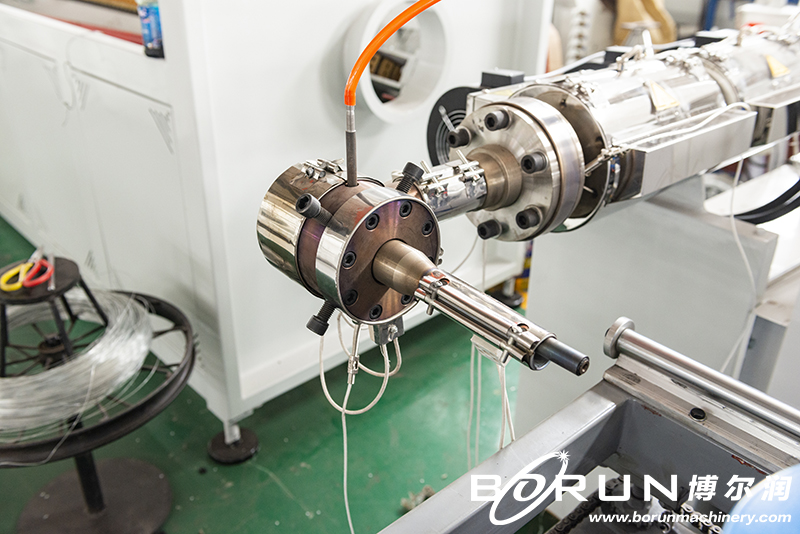

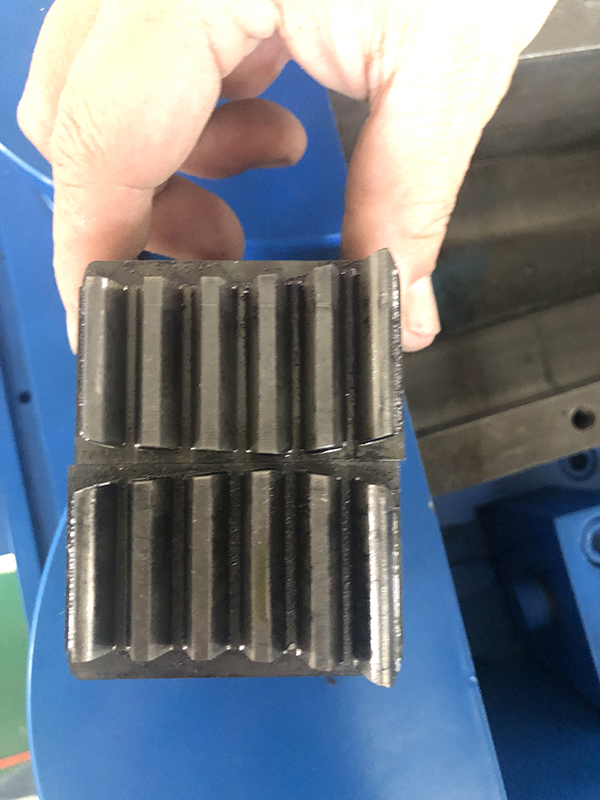

The high speed corrugated pipe production line adopts PLC control system, which is complete functions and easy operation, has linkage functions. When power cut happens in the process of production, it can effectively protect the safety of equipment and molds. It uses a whole closed track to transfer molds, stable operation and high production efficiency guarantee the fastest production reate reaching 25 meters per minute. Equipped with one mold with double chambers may save a considerable cost for customers.

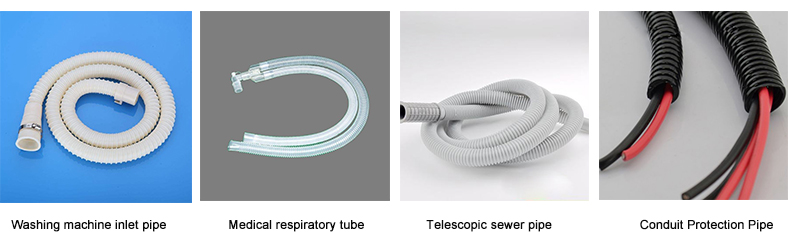

Application:

The high speed corrugated pipe production line adopts PLC control system, which is complete functions and easy operation, has linkage functions.

When power cut happens in the process of production, it can effectively protect the safety of equipment and molds. It uses a whole closed track to transfer molds, stable operation and high production efficiency guarantee the fastest production reate reaching 25 meters per minute. Equipped with one mold with double chambers may save a considerable cost for customers.

Technical Parameters:

Features:

Gear driven machine with higher production speed;

Easy operation, equipped with linkage functions;

Safety protect of equipment in case suddenly power cut;

Stable operation and high efficiency;